SALES

Our available DC motors

Moteur électrique AIMANT PERMANENT

Caractéristiques

Application :

- Convoyeur,pompe ,mixer

Caractéristiques :

- Torque constant, 20 :1

- Très grande précision tachometre intégré

- Stainless, washdown

Moteur électrique TACHOMETRE

Caractéristiques

- Application pour boucle de retroaction

- Model 45/50/60/90 volts dc

- Avec arbre et/ou bride

OUR SERVICES

Our DC motor service center

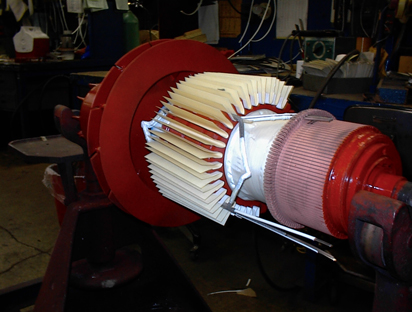

- Main pole and interpole winding

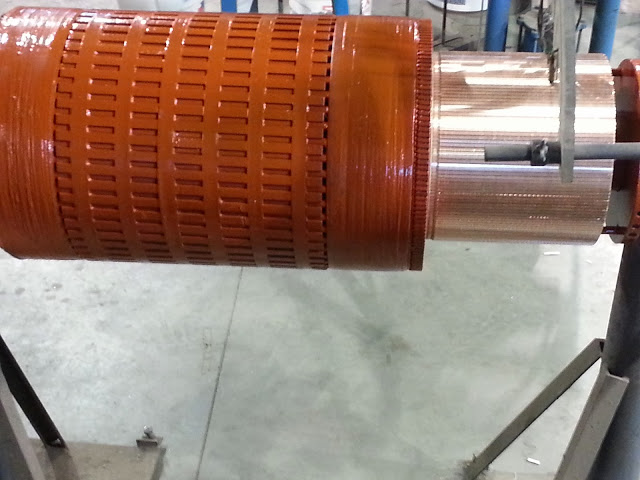

- Armature winding

- Exciter pole winding

- High frequency winding audit

- Selector switch boring

- Neutral point checkup

- Spring tensions checkup

Autres services offerts

- Laser alignment

- Infrared thermography

- Dielectric testing (high-potential testing)

- Surge testing

- Dynamic balancing

- Repair for all types of pumps

- Generator

OUR CERTIFICATIONS

Rebuilding certifications

This certification includes:

- Field coil armature testing

- 30-minute dynamic testing

- Motor disassembly

- Voltage drop test

- Verification and repair of all mechanical adjustments

- Shaft runout tolerance checkup

- Steam cleaning and drying of all components

- Grooving of the collector, if necessary

- Windings, re-isolation, if necessary

- Line replacement, if necessary

- Painting of the inner components

- Winding and bearing replacement

- Brush replacement, if necessary

- Reassembling

- Final testing

- Painting

Rewinding certification

This certification covers:

- Disassembly and cleaning of the unit

- Routine testing (watt loss/stator/dielectric)

- Complete mechanical measurement

- Allowable tolerancese

- 424 cycles high-frequency testing

- Rotor and stator thermal testing

- High tension coils (H) manufacturing

- impregnation of H class stator

- 2-3 cycle oven baking

- Dielectric testing and DC/CA tension testing

- Reassembly and painting

- 30-minute testing on an engine test bench